|

MODEL : GP 1600 | |

| Working area | 1600 x 1200 mm |

| Working area height | 950 mm |

| Speed | 1 – 1700 mm/sec |

| Dimensions without console (W x D x H) | 2270 x 1770 x 2500 mm |

| Dimensions with console (W x D x H) | 2600 x 2200 x 2500 mm |

| Weight | 420 Kg |

| Power supply | 220/400 V – 50/60 Hz |

Compared to manual execution, GP 1600 automatic gluing plotter permits to automate and speed up the selective gluing operation made on flat patterns, increase productivity and allow to reduce the number of operators involved in the complete cycle of gluing and assembling.

This machine guarantees maximum cleanliness, superior and consistent quality in glue deposition, together with absolute repeatability and accuracy of trajectories.

This machine guarantees maximum cleanliness, superior and consistent quality in glue deposition, together with absolute repeatability and accuracy of trajectories.

Given the easiness and speed for new operations setup, its usage is indicated and already profitable for small runs of production.

GP 1600 gluing plotter is used in different sectors such as cardboard and paper industry, packaging, coating and other.

Entirely designed and manufactured by Angeleri (both for mechanical/electronic parts and CAD-CAM software), GP 1600 two axes plotter has a “portal” configuration with fix work table. As an option, one or two vertical feeding systems are available. These systems allow to load sheets of material from the top (for over 600 mm in height) and automatically lift and position the sheets at the required working height at the end of each operation.

The X and Y axes movement (linear or interpolated) is provided by drives and motors (brushless type) controlled by the proprietary CAD-CAM system, installed on machine board on an adjustable support.

The X and Y axes movement (linear or interpolated) is provided by drives and motors (brushless type) controlled by the proprietary CAD-CAM system, installed on machine board on an adjustable support.

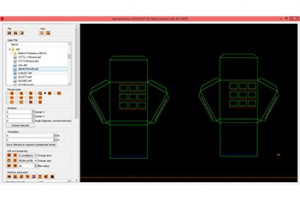

The CAD software allow the operator to easily design on machine board required gluing trajectories, thanks to an intuitive user interface and leaving to the operator the flexibility to choose one of the following mode :

• Using the manual axes movement buttons, the operator move the plotter along the desired deposition path, which is instantly highlighted on the working plan by a laser sensor, and save it.

• By means of an intuitive user graphic interface, the operator can easily draw with a mouse on the PC monitor lines, polilines, circles and arcs that compose the gluing trajectory.

Moreover, it is possible to import gluing trajectories already drawn remotely by a CAD system on the design of parts to be glued, using the standard exchange format DXF.

Moreover, it is possible to import gluing trajectories already drawn remotely by a CAD system on the design of parts to be glued, using the standard exchange format DXF.

It is possible to assign different colors to imported or generated gluing trajectories, according to the type of adhesive to be used for different segments (eg. red color for Hot Melt line nozzle, white color for Vinylic line nozzle, etc.)

Gluing paths can easily be modified at any time, directly on machine board.

The operator can add or delete segments or change the execution sequence, as well as define specific waiting times.

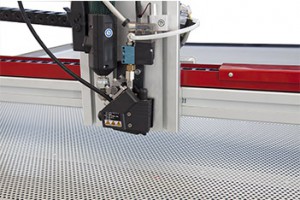

The adhesive is deposited by means of a nozzle, connected to the adhesive tank for the specific operation. The tool head can install up to 3 different nozzles, for the following type of glue deposition : Hot Melt line – Hot Melt spray – Vinylic line. The distance between the nozzle and the material to be glued is adjustable.

GP 1600 plotter is equipped with double photoelectric safety barriers type 2, to guarantee the necessary protection during working operations.

GP 1600 plotter is equipped with double photoelectric safety barriers type 2, to guarantee the necessary protection during working operations.